Water quality plays a critical role in industrial and commercial operations. From manufacturing processes and food production to hospitality, healthcare, and pharmaceuticals, clean and purified water is essential for efficiency, safety, and regulatory compliance. One of the most reliable and widely used water purification technologies is the Reverse Osmosis (RO) plant. Installing an industrial or commercial RO plant requires careful planning, technical understanding, and professional execution to ensure long-term performance and cost efficiency.

This blog explains the complete process of installing a reverse osmosis plant for industrial and commercial applications, covering planning, installation steps, and key considerations.

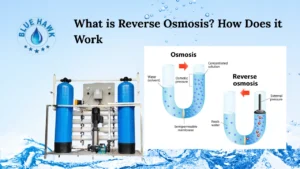

What Is Reverse Osmosis Technology?

A Reverse Osmosis plant is a water purification system that removes dissolved salts, impurities, chemicals, microorganisms, and suspended solids by forcing water through a semi-permeable membrane under pressure. The RO membrane allows only clean water molecules to pass through while rejecting contaminants.

Industrial and commercial RO plants are designed to handle large water volumes and are customized based on raw water quality, required output capacity, and end-use applications.

Importance of RO Plants in Industrial and Commercial Setup

RO plants are essential for industries and commercial facilities because they:

- Ensure consistent water quality

- Protect machinery and boilers from scaling

- Improve product quality

- Reduce chemical consumption

- Meet environmental and regulatory standards

- Lower long-term operational costs

Industries such as food & beverage, pharmaceuticals, textiles, power plants, hotels, hospitals, and manufacturing units heavily rely on RO systems.

Components of a Reverse Osmosis (RO) Plant

- Raw Water Feed Pump – Supplies water from the source to the RO system at required pressure.

- Pre-Treatment System – Includes sand filter, carbon filter, and softener to remove suspended solids, chlorine, and hardness.

- Micron Cartridge Filter – Removes fine particles to protect the RO membrane.

- High-Pressure Pump – Pushes water through the RO membranes for effective separation of impurities.

- RO Membranes – Semi-permeable membranes that remove dissolved salts, chemicals, and contaminants.

- Membrane Housing – Holds and protects the RO membranes under high pressure.

- Control Panel – Manages system operation, safety interlocks, and automation.

- Flow Meters and Pressure Gauges – Monitor water flow and system pressure.

- Chemical Dosing System – Prevents scaling and fouling of membranes.

- Permeate (Product Water) Line – Carries purified water for use or storage.

- Reject Water Line – Discharges concentrated impurities.

- Post-Treatment Unit (Optional) – UV, ozonation, or pH correction for final water polishing.

Industrial RO Plant vs Commercial RO Plant

An industrial RO plant is engineered for large-scale and continuous water purification where water quality directly impacts production processes. These systems are widely used in industries such as pharmaceuticals, food and beverage processing, textiles, power plants, and manufacturing units. Industrial RO plants are highly customized based on raw water analysis, required output quality, and process demand. They operate at higher pressures, include advanced pre-treatment systems, and are often fully automated with PLC or SCADA controls to ensure consistent performance. Although the initial cost and maintenance requirements are higher, industrial RO plants provide long-term reliability, protect equipment, and meet strict quality and regulatory standards.

Key points – Industrial RO Plant:

- High-capacity water treatment systems

- Customized design for process-critical applications

- Advanced pre-treatment and automation

- Suitable for continuous industrial operations

A commercial RO plant, on the other hand, is designed to meet moderate water purification needs, mainly for drinking, cooking, and general utility purposes. These plants are commonly installed in hotels, hospitals, offices, schools, restaurants, and malls. Commercial RO plants usually have lower capacities, simpler configurations, and basic automation or manual operation. They are easy to operate, require minimal technical expertise, and involve lower installation and operating costs, making them ideal for commercial establishments.

Key points – Commercial RO Plant:

- Medium to low capacity systems

- Standard or semi-customized design

- Easy operation and maintenance

- Cost-effective solution for commercial use

In conclusion, the choice between an industrial and a commercial RO plant depends on water demand, application, and quality requirements. Industrial RO plants are suitable for high-volume, process-oriented operations, while commercial RO plants offer an economical and efficient solution for institutions and businesses with standard water purification needs.

Factors to Consider Before Installing a Reverse Osmosis (RO) Plant

- Raw Water Quality – Test TDS, hardness, turbidity, and contaminants to select the right RO design.

- Required Water Capacity – Determine daily or hourly water demand.

- Intended Application – Drinking, process water, boiler feed, or utility use.

- Pre-Treatment Needs – Sand filter, carbon filter, softener, or dosing system requirement.

- Space Availability – Ensure sufficient area for installation and maintenance.

- Recovery Rate & Reject Management – Plan for water recovery and reject disposal.

- Power Supply – Confirm availability of stable electricity.

- Automation Level – Manual, semi-automatic, or fully automatic system.

- Operating & Maintenance Cost – Consider chemicals, membrane replacement, and energy usage.

- Service & Support – Choose a reliable supplier with strong after-sales support.

Steps to Install a Commercial or Industrial RO Plant

- Raw Water Testing and Analysis: The first step is to analyze the raw water source to determine TDS, hardness, pH, turbidity, and other contaminants. This helps in selecting the correct RO system design and capacity.

- Capacity and System Design Selection: Based on water demand and quality, the appropriate RO plant capacity, recovery rate, and automation level are finalized to suit commercial or industrial requirements.

- Pre-Treatment System Installation: Pre-treatment units such as sand filters, carbon filters, softeners, or chemical dosing systems are installed to protect RO membranes and ensure consistent feed water quality.

- RO Unit and High-Pressure Pump Installation: The RO skid, membranes, and high-pressure pump are installed on a leveled foundation, with proper alignment and secure mounting.

- Piping, Electrical, and Instrumentation Setup: Inlet, outlet, and reject pipelines are connected, along with electrical wiring, control panels, and monitoring instruments.

- Post-Treatment and Storage Arrangement: Optional post-treatment systems like UV or pH correction units are installed, followed by treated water storage tanks.

- System Commissioning and Trial Run: The plant is flushed, tested, and run under supervision to check performance, pressure, flow rates, and water quality.

- Operator Training and Handover: Operators are trained on daily operation, maintenance, and safety, ensuring smooth and efficient long-term operation.

Benefits of RO Plants

- High-Quality Purified Water – Removes dissolved salts, chemicals, and contaminants, ensuring safe and consistent water quality.

- Improved Product Quality – Essential for industries where water quality directly affects the final product.

- Equipment Protection – Prevents scaling and corrosion in boilers, chillers, and machinery, extending equipment life.

- Cost Savings – Reduces dependence on bottled or tanker water and lowers maintenance costs over time.

- Consistent Performance – Delivers uniform water quality regardless of fluctuations in raw water.

- Environment Friendly – Supports water reuse and sustainable water management practices.

- Customizable Capacity – Systems can be designed for specific commercial or industrial requirements.

- Regulatory Compliance – Helps meet health, safety, and environmental standards.

Conclusion

Installing a reverse osmosis plant for industrial or commercial use is a strategic investment that ensures water purity, operational efficiency, and long-term cost savings. From water analysis and system design to installation and commissioning, every step plays a crucial role in system performance.

By choosing an experienced Commercial RO Plant manufacturer like Yash Water Pvt. Ltd., businesses can ensure smooth installation, reliable operation, and consistent water quality tailored to their specific needs. A well-installed RO plant not only improves productivity but also supports sustainable water management for the future.